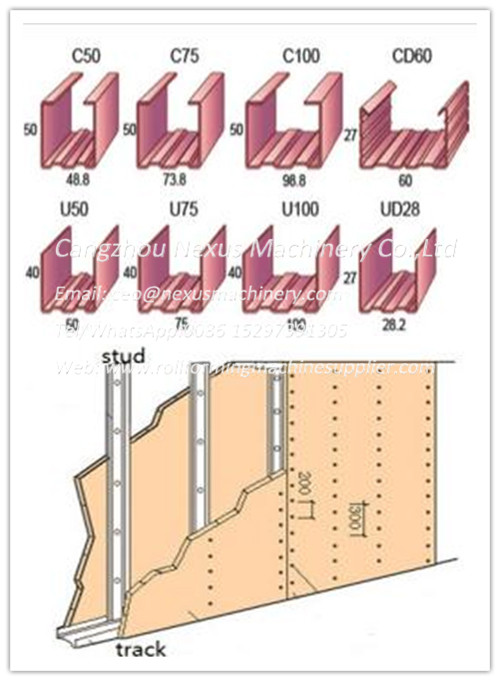

Stud and track roll forming machine also named CU roll forming machine. It is combined with stud roll forming machine and track roll forming machine.

stud and track roll forming machine can design different shapes and sizes ,meanwhile we can standardize or customize all stud and track.

C Stud and track roll forming machine has five basic elements, decoiler, leveling, roll forming machine, cutting system,run-out table. Certainly we also add punching system and press logo according to customer’s need.

1.Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

2.Feeding and leveling

This part will level coil to make sure it is neat clean and straight.

stud and track roll forming machine

we design machine frame as gantry style, the thickness of side plane is about 25mm. And the roller material is GCr12MoV,we will improve the driving by gear. And the diameter of shaft is 50mm. The roller stations will be different design by different shape and size to confirm the perfect shape for the stud and track profiles.

4.Pressing logo ,punching and cutting system for stud roll forming machine

We make them with one unit. Whats more, we also design this unit with unstop, that will save much labor and have a good productivity.

5. Electric Control System

We adopt PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.