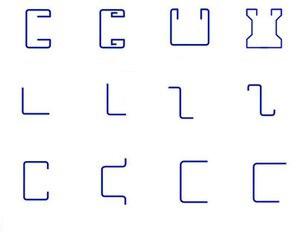

Fully automatic Interchange C Z purlin roll forming machine could produce C purlin and Z purlin in one machine, what’s more, one C Z purlin roll forming machine could produce many sizes.

The working process of C Z purlin roll forming machine:

Decoiler--guiding---leveling--roll forming-(interchange-size-automatically)-- punching-- cut to length-- output table.

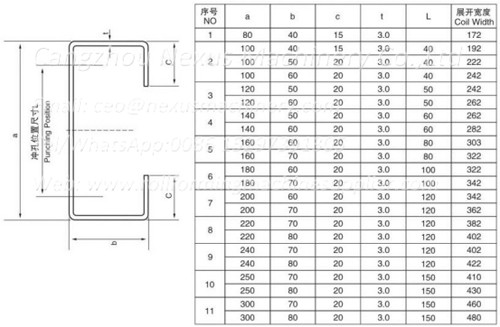

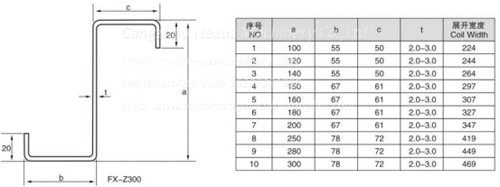

Here is the sizes of C purlin and Z purlin we can do:

The picture for automatic Interchange C Z purlin roll forming machine:

Main parameters of C Z purlin roll forming machine:

| Name | Parameters |

| Number of forming stations | 18 groups |

| Roller material | Gcr15 steel and quench treatment hardness 55-58, chrome coated 0.05mm |

| Shaft material | Bearing steel |

| Transport | Double row chain by 40mm |

| Totally motor Power | 24.5Kw |

| Working speed | 10m--15m/min(Exclude cutting time) |

| Supported material thickness | 1.2-3mm |

Character of main structure:

a)The structure is simple and the appearance of the machine is beautiful because we adopt the

shape-steel structure and most of the connector is screw which makes the machine flexible

and stronger.

b) All the components of machine are from brand-famous enterprise so that they ensure the

machine normal function is very effective.

c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise

and the finished product clear without deforming.

d) It is very easy to install the equipment and suitable for producing in the factory.

e) Low noise with high efficiency

f) The width of the profile can be automatic adjusted and the last 10 roller stations can be

overturned to make C&Z purlin