corrugated roof roll forming machine

Corrugated roof roll forming machine can produce different shapes of steel corrugated roof according to different profile drawings.

A complete corrugated roof machine includes uncoiler, roll forming machine, cutting part and PLC system. We simply program the pieces and length we need in the computer, then the roof roll forming machine produces it automatically. The machines are easy to operate and running stable.

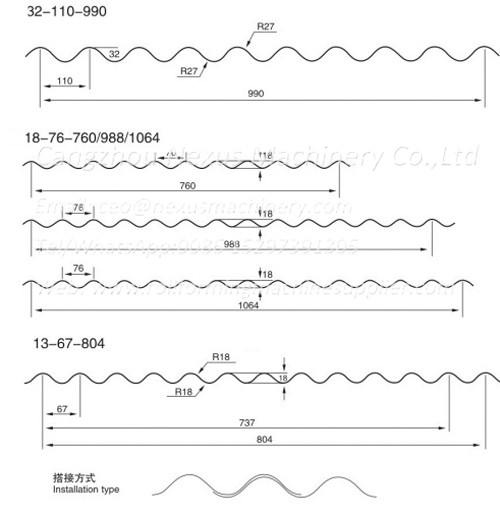

Below are some popular profile drawings in the market:

| Main parameter for corrugated roof roll forming machine |

| Manual Uncoiler |

| Feeding Guider |

| Roll forming machine |

| Hydraulic Cutting system |

| PLC Control System |

| Runout Table |

| Specifications of corrugated roof machine | |

| Uncoiler | Manual Uncoiler |

| Inner diameter | 450-550mm |

| Outer diameter | 1250mm. |

| Loading weight | 5T |

| roof roll forming machine | |

| Forming speed | 8—12m/min. |

| Forming steps | 14 stations |

| Material of Shafts | 45# high-quality steel |

| Diameter of Shafts | 70mm |

| Material of Roller | high quality 45#steel coated with hard chrome 0.05mm. |

| Thickness of Siding Plate | 18mm |

| Transmission | by chain-brackets |

| Material of Chains | 45#steel with heat treatment: HRC45-50° |

| Motor Power | 5.5 KW |

| Cutting System of this corrugated roof roll forming machine: | |

| Material of blade | Cr12 with quenched treatment 60-62 |

| Hydraulic Power | 3 KW |

| Cutting Length and Quantity | Clients can set the required length and quantity on the PLC touch screen |

| Control System of corrugated roof machine | |

| Panasonic PLC Control system,touch screen, frequency converter | |

| Voltage | 380V/50HZ/3phase |

| Automatically measure the length and quantity | |