Our design team communicate with many customers face to face , we talked about the processing efficiency and processing quality of automatic steel C purline roll forming machine, and we improve the design of C purline roll forming machine.

The new C purline machine have three advantages:

1.Changing sizes: We improve the new spacers and shorten the time to ten minutes.

2.Punching holes: We change the post-punching to pre-punching, and make the machine

more efficiency.

3.The leveling: We add 7 leveling rollers before roll forming rollers, and make them with 80mm

diameter, that makes coils sheet more flat.

The parameter of C purline roll forming machine for you reference:

| working speed | 15m/min |

| roll station | 12 stations |

| material of roller | GCr15steel, quenched 58-62° |

| material of main shaft | 45﹟forge steel |

| main power | 15KW |

| forming thickness | 1.5-3.0mm |

| transmission | chain |

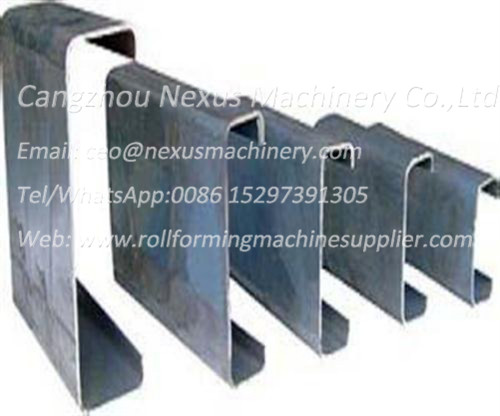

The photos for automatic steel C purline roll forming machine for your reference: